General Atomics Aeronautical Systems Inc. adopted FDM additive manufacturing to replace composite UAV parts, lower tooling costs, and accelerate part delivery.

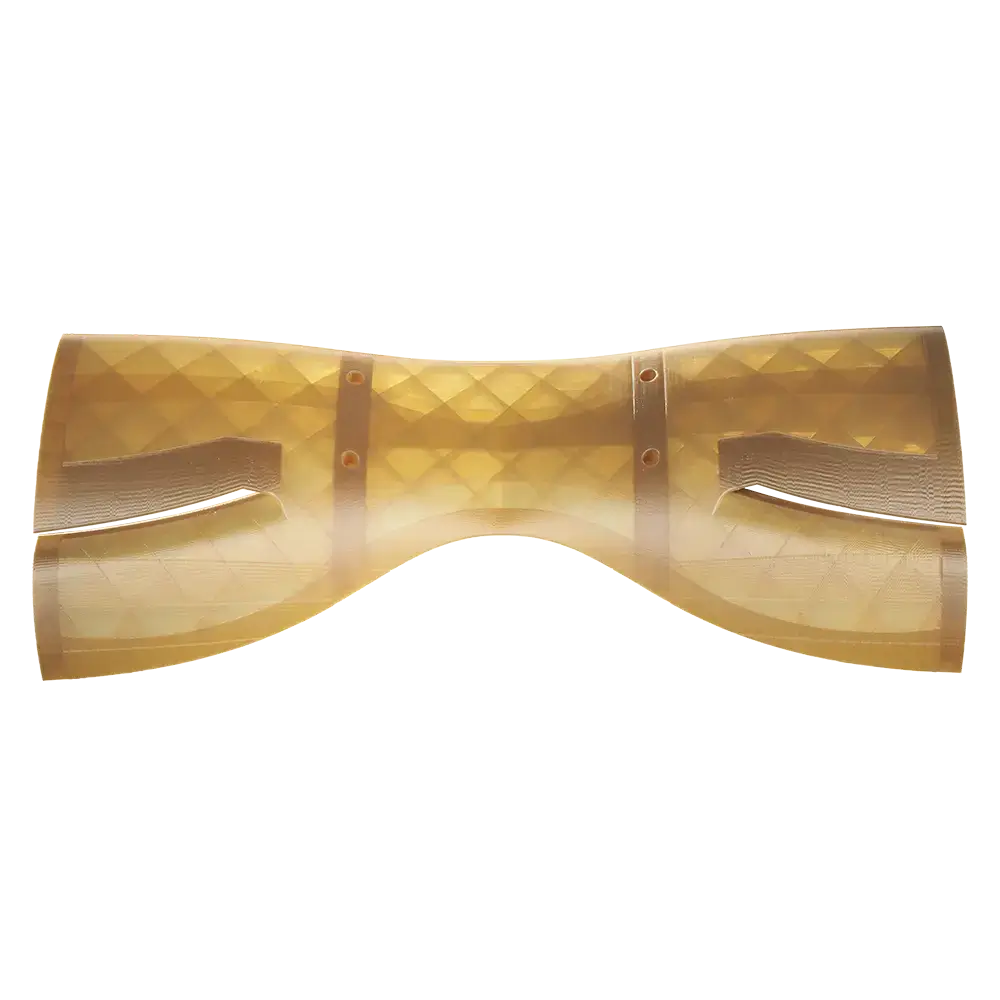

This case study highlights how high-performance materials like ULTEM 9085 enabled functional, airworthy components without the delays of traditional fabrication.

The result: over $2 million saved, 300+ parts produced, and scalable deployment across the MQ-9B SkyGuardian platform.