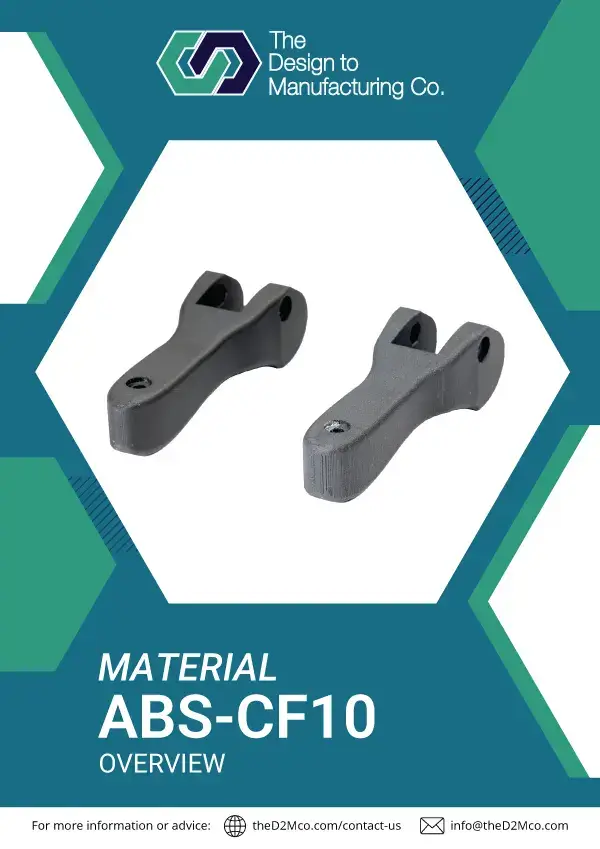

ABS-CF10 delivers carbon fiber-reinforced strength and lightweight performance for durable FDM 3D printed tooling, fixtures, and end-use parts.

ABS-CF10 is an advanced thermoplastic infused with 10% chopped carbon fiber, providing exceptional stiffness and strength while reducing weight. This material is engineered for demanding environments where robust performance and dimensional stability are essential.

The carbon fiber reinforcement in ABS-CF10 enhances mechanical properties, making it ideal for manufacturing jigs, fixtures, and functional parts that must withstand stress without adding unnecessary weight.

ABS-CF10 combines the ease of printing associated with standard ABS and the added benefits of carbon fiber. It delivers smooth surface finishes, excellent dimensional accuracy, and reduced warping, ensuring consistent production quality.

From industrial tooling to low-volume production components, ABS-CF10 is optimized for creating durable, functional parts that meet the needs of aerospace, automotive, defense, and manufacturing sectors.

Download the full material sheet for key details on performance and usage. A quick, practical reference for technical and commercial teams.

Sign up for articles, guides, and industry news

© Copyright 2025 – The Design to Manufacturing Company. Use of site constitutes acceptance of our [Privacy Policy] and [Terms & Conditions].