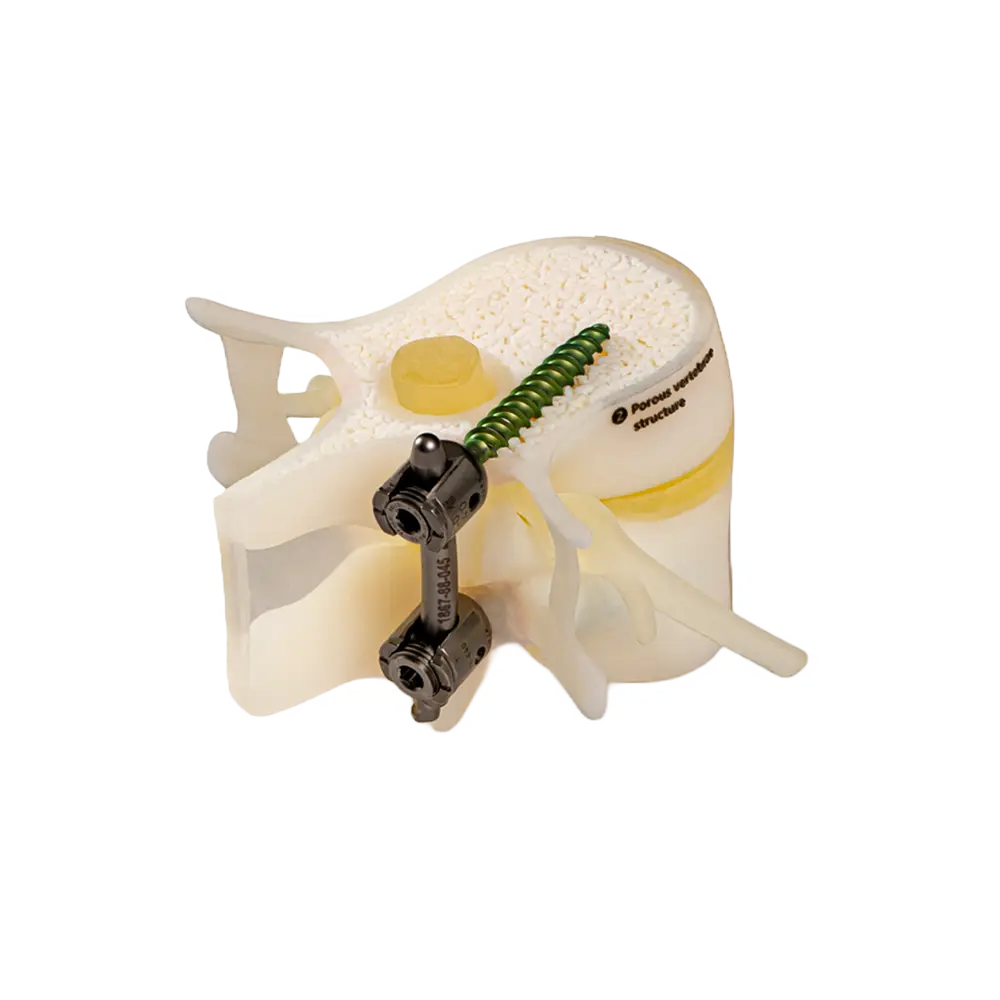

BoneMatrix™ is a rigid, translucent material designed to replicate the look and feel of human bone, ideal for surgical training, pre-surgical planning, and medical modeling.

BoneMatrix™ is a 3D printing material developed to simulate the structure and mechanical behavior of real bone. With high rigidity and a semi-translucent appearance, it enables the creation of anatomical models that respond predictably to cutting, drilling, and sawing, offering hands-on realism for procedural training and prototyping.

This material is ideal for practicing procedures such as orthopedic drilling, bone segmentation, and implant fitting. It holds up under pressure and delivers lifelike feedback, making it suitable for training environments that demand precision and repeatability.

BoneMatrix™ allows educators to present accurate skeletal structures that feel and behave like real bone. Medical trainees benefit from working with physical models that enhance spatial understanding, procedural skill, and diagnostic interpretation.

The rigidity and detailed resolution of BoneMatrix™ make it suitable for testing implants and surgical tools. Developers and technicians can assess fit, alignment, and interaction with bone-like material prior to clinical trials or patient procedures.

BoneMatrix™ supports clean geometries, stable support integration, and minimal post-processing. Its dependable performance makes it a valuable material in any advanced medical modeling workflow.

Download the full material sheet for key details on performance and usage. A quick, practical reference for technical and commercial teams.

Sign up for articles, guides, and industry news

© Copyright 2025 – The Design to Manufacturing Company. Use of site constitutes acceptance of our [Privacy Policy] and [Terms & Conditions].