FDM Support Materials enable complex geometries, reduce post-processing time, and ensure precision in Fused Deposition Modeling for prototypes, production parts, and tooling.

FDM Support Materials are engineered to stabilize overhangs, internal cavities, and intricate geometries throughout the Fused Deposition Modeling process. These materials ensure dimensional accuracy, clean finishes, and structural integrity while streamlining post-processing.

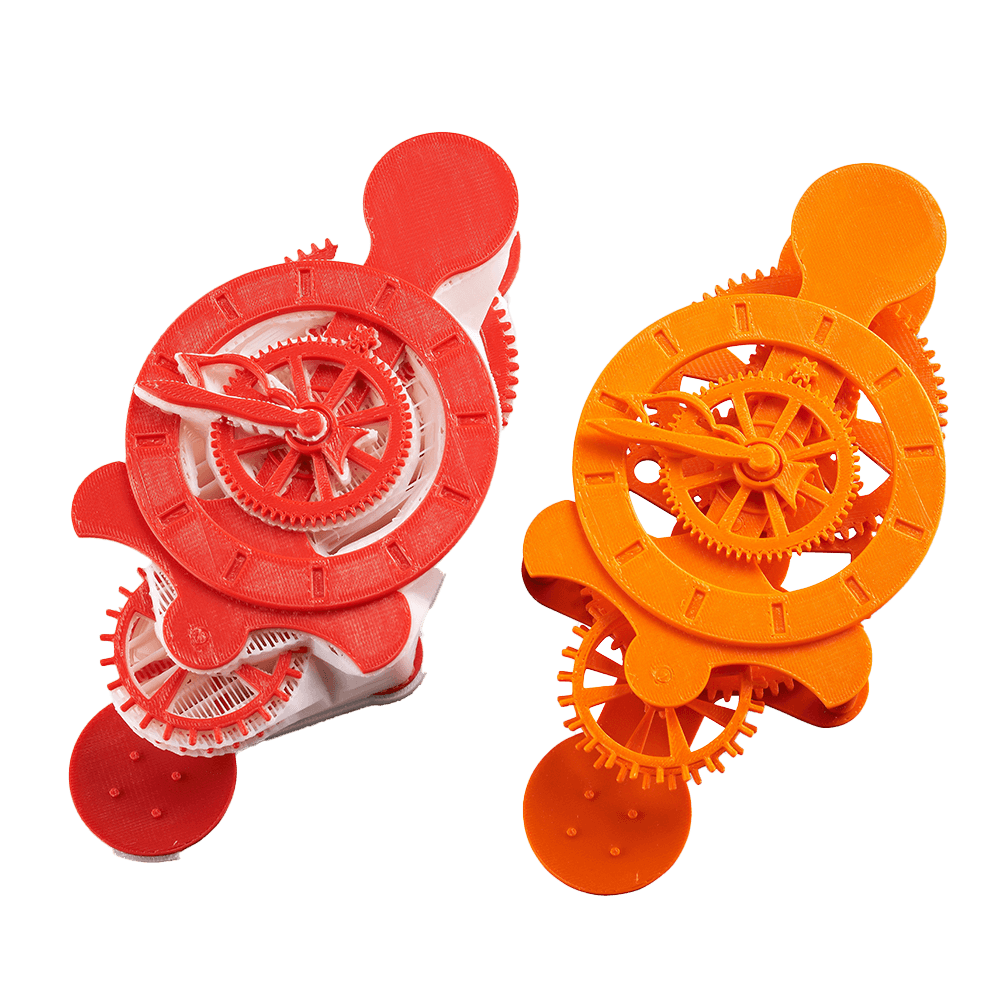

With both breakaway and soluble formulations, FDM Support Materials adapt to various design requirements. Breakaway supports offer fast, tool-assisted removal, while soluble supports dissolve in a hands-free solution, ideal for delicate or fully enclosed structures.

By minimizing manual finishing and supporting complex features, these materials improve overall print success rates. They are optimized for compatibility with a wide range of high-performance FDM thermoplastics, ensuring seamless integration into production workflows.

For designs with hard-to-reach areas or delicate features, soluble support materials offer a convenient solution. These supports dissolve in a water-based solution, enabling hands-free removal and preserving fine details without the risk of damage. This method is particularly beneficial for parts with internal channels or complex assemblies.

For simpler designs or when immediate support removal is desired, breakaway support materials can be manually detached from the printed part. This approach eliminates the need for immersion tanks and is effective for structures where supports are easily accessible.

Selecting the appropriate FDM support material depends on part geometry, material compatibility, and post-processing preferences. Soluble support materials are best for complex prints requiring hands-free removal, while breakaway supports offer faster, manual removal for robust engineering-grade thermoplastics.

FDM Support Materials improve print success rates, part durability, and post-processing efficiency, ensuring high-quality prototypes and end-use parts across industries such as aerospace, automotive, and medical manufacturing.

Download the full material sheet for key details on performance and usage. A quick, practical reference for technical and commercial teams.

Sign up for articles, guides, and industry news

© Copyright 2025 – The Design to Manufacturing Company. Use of site constitutes acceptance of our [Privacy Policy] and [Terms & Conditions].