PC-ABS combines the strength and heat resistance of polycarbonate with the flexibility of ABS for durable, high-performance FDM 3D printed parts across demanding industries.

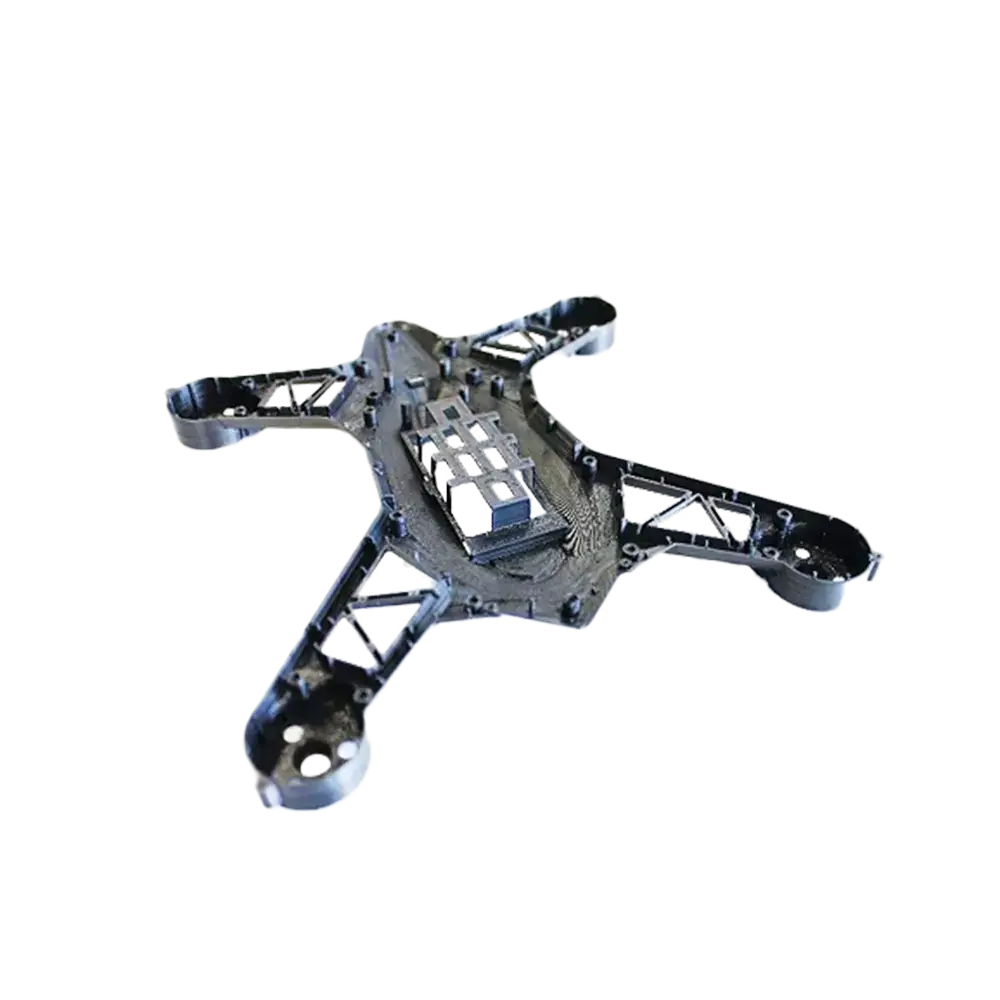

PC-ABS combines the best properties of polycarbonate and ABS, delivering exceptional toughness, impact resistance, and thermal stability. This makes it ideal for creating durable parts that can withstand mechanical stress and elevated temperatures without compromising performance.

Designed for demanding environments, PC-ABS is widely used to produce end-use components, functional prototypes, and manufacturing tools. Its excellent surface finish and dimensional stability ensure that printed parts meet industrial-grade requirements, whether for production or validation purposes.

From aerospace to automotive and industrial manufacturing, PC-ABS supports a broad range of applications. Whether you’re producing robust housings, jigs, fixtures, or replacement parts, this material offers the reliability and strength needed for real-world use cases.

Download the full material sheet for key details on performance and usage. A quick, practical reference for technical and commercial teams.

Sign up for articles, guides, and industry news

© Copyright 2025 – The Design to Manufacturing Company. Use of site constitutes acceptance of our [Privacy Policy] and [Terms & Conditions].