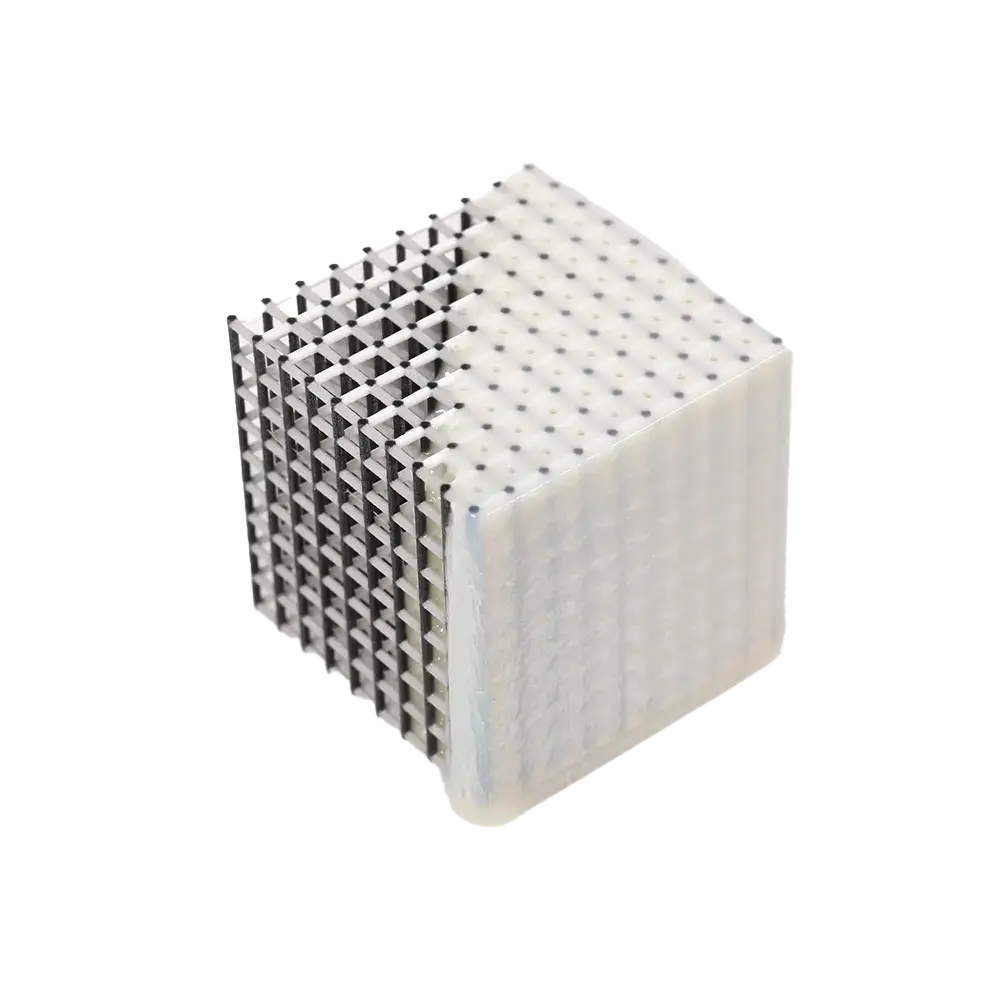

WSS150 PolyJet Support Material is a water-soluble, user-friendly solution for complex 3D prints, ideal for delicate parts and internal cavities with minimal post-processing.

WSS150 PolyJet Support Material is engineered to streamline the production of intricate prototypes and parts that include fine features, deep internal cavities, or delicate overhangs. This water-soluble support material is specifically formulated for seamless removal with tap water – eliminating the need for manual labor or harsh chemicals in post-processing.

Whether you’re producing medical models, small-batch consumer goods, or multi-material prototypes, WSS150 offers a clean, efficient solution that helps preserve the fine detail and surface quality of your parts. Its compatibility with PolyJet technology ensures it works smoothly with a wide range of rigid and flexible materials, making it a staple for rapid prototyping and functional design validation.

WSS150 dramatically cuts down on labor by allowing supports to dissolve in regular tap water. This simplifies workflow and improves throughput, especially in high-mix or fast-paced production environments. With no need for manual removal or secondary equipment, engineers and designers can focus on iterating and optimizing, not cleaning parts.

When printing parts with small internal channels, tight clearances, or thin-walled structures, traditional support removal can damage the final object. WSS150 offers gentle, complete support removal without compromising part quality – perfect for complex mechanical prototypes or patient-specific medical models where dimensional accuracy is critical.

Unlike traditional supports that require caustic soda or specialized disposal, WSS150’s water solubility offers a safer, more eco-friendly post-processing option. It’s ideal for institutions or businesses focused on reducing chemical use and waste, supporting internal sustainability goals while also improving lab safety.

WSS150 integrates seamlessly with PolyJet materials, enabling the creation of multi-material prototypes with different textures, colors, or mechanical properties in a single print. Whether simulating an overmolded grip, anatomical model, or product assembly, you can trust that support removal won’t interfere with the part’s look or function.

From industrial jigs and fixtures to fit testing and functional validation, WSS150 is the support material of choice for engineers demanding precision and reliability. The clean removal process ensures that critical tolerances and smooth surfaces are maintained, making it easier to move from prototype to production.

Download the full material sheet for key details on performance and usage. A quick, practical reference for technical and commercial teams.

Sign up for articles, guides, and industry news

© Copyright 2025 – The Design to Manufacturing Company. Use of site constitutes acceptance of our [Privacy Policy] and [Terms & Conditions].