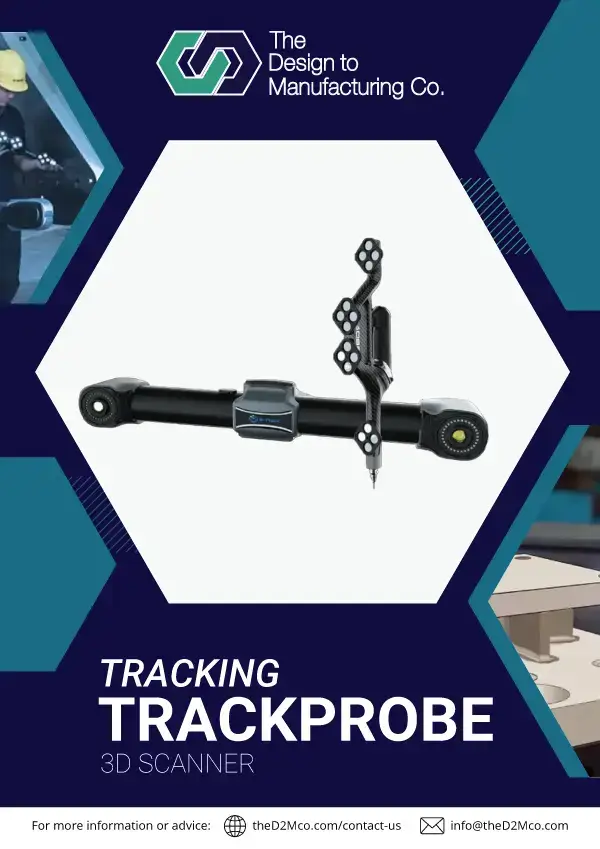

The TrackProbe 3D Probing System delivers wireless, high-accuracy coordinate measurement for large parts and industrial applications.

The TrackProbe 3D Probing System is a lightweight, wireless, and metrology-grade solution for accurate 3D coordinate measurement of parts ranging from compact components to large-scale structures. Designed for tough industrial environments, it combines the handheld i-Probe with a high-resolution optical tracker to deliver precise data even in dynamic conditions. Whether you’re inspecting large turbine blades, automotive frames, or aircraft panels, the TrackProbe system ensures speed, flexibility, and exceptional accuracy.

With its lightweight i-Probe (700g) and robust tracking performance, the TrackProbe system provides highly accurate point-by-point measurements without physical contact. It captures precise 3D coordinates for parts up to 12 meters in size, making it ideal for field-based inspection, maintenance, and reverse engineering.

TrackProbe supports both wired and wireless workflows with plug-and-play setup. Operators can switch easily between probing and scanning tasks using compatible systems. Its extended volumetric accuracy, long-range measurement capacity, and ergonomic design enable high-efficiency measurement in real-world manufacturing environments.

The TrackProbe system is perfect for industries requiring fast, reliable, and repeatable probing on large parts and in tough production conditions. From turbine repair and mold validation to vehicle assembly and infrastructure maintenance, it delivers actionable measurement results with minimal setup time.

Aerospace: Contact-free inspection of aircraft structures and tooling

Automotive: Reverse engineering, tool path verification, and part validation

Defense: Probing of tactical vehicle parts, weapons housings, and assemblies

Energy, Process & Utilities: Measuring worn or legacy parts in oil & gas, turbine blades, and heavy components

Transportation & Mobility: Rail and shipyard component measurement

Mold & Tooling: Accurate mold surface inspection and CAD comparison

The brochure includes key technical data, accuracy benchmarks, and example use cases. Helpful for evaluating fit across inspection, reverse engineering, and production tasks.

Sign up for articles, guides, and industry news

© Copyright 2025 – The Design to Manufacturing Company. Use of site constitutes acceptance of our [Privacy Policy] and [Terms & Conditions].