Additive Manufacturing for Space: A New Era of Efficiency

Additive manufacturing (AM), commonly known as 3D printing, significantly enhances the way aerospace components are designed and produced. By allowing complex parts to be printed directly from digital models, AM drastically reduces the number of components and simplifies assembly processes. These capabilities enable cost savings and faster production cycles crucial for the demanding timelines of space exploration.

The Benefits of Additive Manufacturing in Aerospace

AM is uniquely suited to aerospace because of its flexibility, efficiency, and material adaptability. Traditional manufacturing often involves extensive welding and complex assemblies. Conversely, AM allows intricate designs to be printed as single, cohesive units. This drastically reduces assembly times, minimizes potential points of failure, and enhances component reliability under the rigorous conditions of space missions.

Additionally, AM technology supports a broad range of materials, including high-performance metals such as titanium, aluminum, and nickel-based alloys. These 3D printing materials offer essential characteristics needed for aerospace applications, including high-temperature resilience, strength-to-weight efficiency, and durability under intense pressure.

Streamlining Spacecraft Propulsion Systems

One of the critical applications of additive manufacturing in aerospace is in propulsion system development. Components like turbopumps and injectors, which previously involved hundreds of parts, are now produced using AM methods, significantly reducing complexity and improving performance.

AM-produced components are especially beneficial in propulsion systems due to their ability to withstand extreme pressures and temperatures. For instance, traditionally manufactured turbopumps can require extensive machining and multiple welds. Using selective laser melting and electron beam melting processes, these complex parts can be manufactured more reliably and efficiently.

The result is a more robust component with fewer points of failure, higher efficiency, and reduced weight, essential factors in the demanding conditions of rocket propulsion systems.

AM’s Role in In-Space Manufacturing

AM technology extends its advantages beyond Earth, promising to transform manufacturing capabilities in space itself. In-space additive manufacturing is crucial for long-duration missions where resupply from Earth may be impractical or impossible.

The International Space Station (ISS) has already demonstrated the viability of AM in microgravity. Utilizing specially adapted 3D printers, astronauts can now produce tools and replacement parts directly aboard the ISS. This significantly reduces the reliance on resupply missions, enhancing mission sustainability and reducing payload costs.

Moreover, research is advancing into using local resources – such as lunar or Martian regolith – to produce construction materials through AM. This capability, known as in-situ resource utilization (ISRU), could drastically cut costs and logistical complexities for building habitats and infrastructure in space.

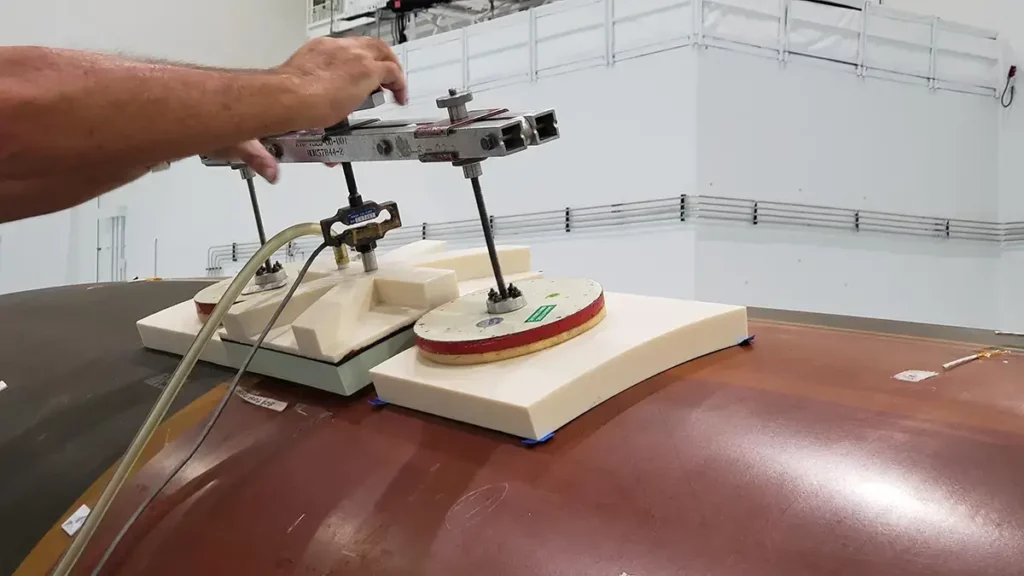

Digital Scanning and Manufacturing Integration

The success of AM in aerospace is bolstered by advanced digital scanning technologies. Structured Light Scanning (SLS) or 3D scanning precisely assesses 3D printed components against their digital models, ensuring exact dimensional accuracy. This technology enables aerospace companies to quickly detect and rectify any deviations, significantly reducing manufacturing time and cost.

Applications of structured light scanning range widely – from evaluating small, intricate components to scanning entire sections of spacecraft. Its accuracy and versatility facilitate precision assembly and integration, crucial for the reliability and success of space missions.

Stratasys Joins Space Supply Chain Council

The Commercial Space Federation (CSF) recently announced the formation of the Space Supply Chain Council (S2C2), naming Stratasys among its inaugural members. S2C2 brings together aerospace manufacturers, software developers, logistics providers, and assembly integration specialists to set industry priorities, recommend policy directions, and address challenges facing the commercial space sector.

This strategic move positions Stratasys alongside prominent industry players such as Applied Aerospace, a leader in precision aerospace structures, and National Air Cargo, renowned for global logistics solutions. With these collaborations, the S2C2 aims to enhance the robustness and resilience of space industry supply chains, fostering advancements critical to ongoing and future space exploration missions.

Stratasys’ involvement underscores the importance and potential of AM in aerospace, emphasizing its commitment to innovation and collaborative development to support aerospace manufacturing and logistics.

Future Prospects and Potential

The future of additive manufacturing in aerospace holds significant promise. AM technology not only streamlines manufacturing processes but also drives innovations in spacecraft design, in-orbit construction, and long-term mission sustainability.

As AM technologies mature and evolve, we can expect further integration into propulsion systems, spacecraft structure fabrication, and even habitat construction for future lunar or Martian colonies. The potential to use locally sourced materials in space to create vital infrastructure represents a groundbreaking shift in mission planning, logistics, and sustainability.

Practical Steps to Adopt AM in Your Aerospace Operations

To harness the potential of additive manufacturing, aerospace organizations can take several practical steps:

- Evaluate AM Potential: Assess your current processes for components that could benefit from consolidation through AM.

- Material Selection: Identify suitable AM materials based on application-specific requirements.

- Digital Tools Integration: Invest in digital manufacturing tools and structured light scanning to ensure precise quality control.

- Collaborative Partnerships: Engage with industry councils and partnerships, like S2C2, to stay ahead of trends, policies, and opportunities.

By implementing these measures, aerospace firms can effectively adopt and benefit from additive manufacturing, positioning themselves competitively in a rapidly evolving industry.

Embrace the Future with Additive Manufacturing

Additive manufacturing stands as a pivotal technology driving innovation, efficiency, and reliability in aerospace. Its capabilities for streamlined production, material versatility, and in-space manufacturing present unprecedented opportunities for the industry.

Aerospace companies looking to enhance their competitive edge and operational efficiencies should consider integrating AM into their manufacturing strategies. The future of aerospace exploration and commercial operations hinges significantly on the adoption and advancement of additive manufacturing technologies.

Request your additive manufacturing consultation today to unlock innovation in aerospace.