In today’s fast-paced and competitive manufacturing landscape, reducing lead times is critical for staying ahead. Long waits for tooling and production can delay product launches, frustrate customers, and impact your bottom line.

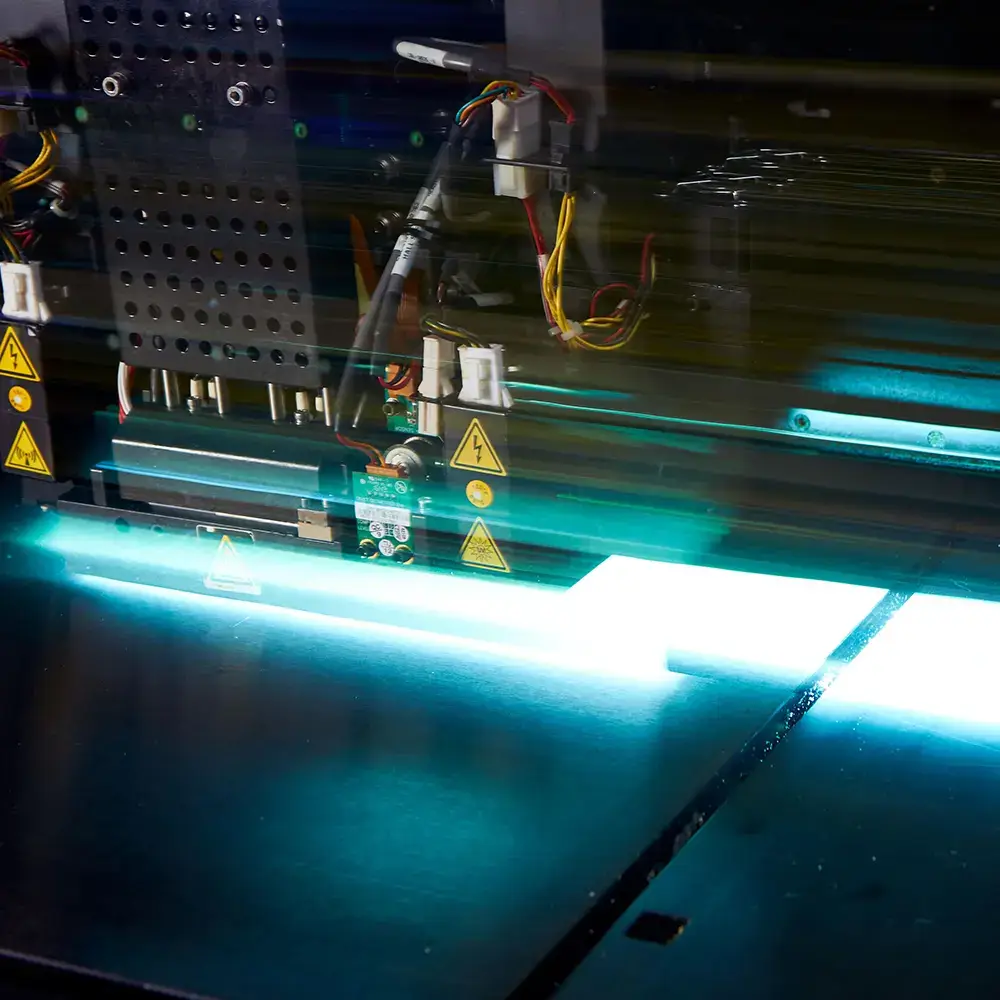

Additive manufacturing (AM), also known as 3D printing, has emerged as a powerful and proven tool to dramatically shorten these timelines.

For over 30 years, the Design to Manufacturing Co. has been at the forefront of the additive manufacturing technology, guiding businesses from initial concept to full-scale adoption.

As a ‘Platinum’ status supplier, we provide the expertise and technology to help you slash your lead times and enhance your competitive edge.

Accelerate Your Tooling Production

Traditional tooling processes are a common source of significant delays. Additive manufacturing offers a direct solution by enabling the rapid creation of jigs, fixtures, and even complex molds in-house and on-demand.

- Medical Device Tooling: Westminster Tool, a medical device OEM supplier, used metal 3D printing to create complex steel mold inserts in just four weeks, cutting their usual eight-week timeline in half. This strategic shift also eliminated more than 110 hours of labor and machining time.

- Aerospace Tooling: In a critical situation, mid-sized aerospace supplier East/West faced an eight-week production delay due to a damaged forming die. By using their in-house Fortus 450mc printer to 3D print a replacement die with carbon fiber-reinforced material, they cut the tooling lead time by an incredible 87%. This allowed them to get the tool in under a week and keep the customer delivery on schedule.

Explore our range of Industrial 3D Printers to see how you can bring this capability in-house.

Streamline Direct Part Production

Beyond tooling, AM is completely changing the production of end-use parts, offering unprecedented speed and efficiency. This is particularly valuable in sectors that demand high performance and rapid turnarounds.

Serving the demanding oil and gas sector, PGV Industries integrated binder jet metal 3D printing into its workflow.

This move successfully cut their lead times by as much as 80%. As a result, the company not only accelerated its production but also cut its inventory requirements by approximately 50%, which freed up significant internal capacity and streamlined their entire operation.

Discover how our Additive Manufacturing Services can optimize your parts production.

Enhance and Expedite Repair Processes

Maintenance, repair, and overhaul (MRO) operations are another area where lead times are critical.

In the aerospace industry, Pratt & Whitney has pioneered an additive manufacturing repair process for components of its Geared Turbofan engine. This innovative approach has reduced repair times by over 60%, significantly improving turnaround times while also lowering tooling costs and reducing dependence on fragile supply chains

Contact us to learn more about creating a Digital Inventory for your spare parts.

The Benefits of Additive Manufacturing

Integrating AM technology delivers clear, measurable advantages for businesses across all industries.

- Unmatched Speed: Move from design to prototype and final product faster than ever, significantly reducing your time-to-market.

- Ultimate Flexibility: Make rapid design changes and iterations without the need for expensive and time-consuming retooling.

- Significant Cost Savings: Lower your operational costs through more efficient processes that reduce labor and material waste.

- Reduced Inventory: Embrace on-demand manufacturing to produce parts as you need them, minimizing the need for large and costly inventories.

Your Partner in Additive Manufacturing Adoption

Additive manufacturing offers a clear path to enhanced efficiency and market responsiveness. However, navigating the technologies, materials, and processes can be challenging.

At the Design to Manufacturing Co., we provide complete, end-to-end solutions to ensure your success. With offices in Athens (Greece), Dubai (United Arab Emirates), and Riyadh (Kingdom of Saudi Arabia), our ‘Platinum’ status team provides everything you need:

- Expert Consultation: Leverage our 30+ years of expertise to identify the best AM opportunities for your business.

- Complete Equipment Supply: From industrial 3D printers to 3D scanners for digitizing your assets.

- Software & Consumables: We provide the software you need for integration and the full range of production-grade consumables.

- Training & Support: Our experts offer comprehensive training and ongoing support to ensure you get the most from your investment.

- Digital Asset Services: If you lack an in-house design team, our experts can create or optimize your digital assets for you.

Take Action: Cut Your Lead Times Today

Are you ready to stop waiting and start innovating? The first step is to assess your current production bottlenecks. Whether it’s in tooling, repairs, or spare parts, additive manufacturing can offer a solution.

Schedule a consultation with our expert team today to discuss a proof-of-concept and begin your journey to faster, more flexible, and more efficient manufacturing.