Additive manufacturing (AM) enables localized, on-demand production, reducing reliance on extended global supply chains. By digitizing spare parts and tooling, companies can minimize inventory costs and respond swiftly to market changes. This approach is particularly effective for low-volume production, spare parts, and rapid prototyping.

The New Blueprint for Industrial Manufacturing

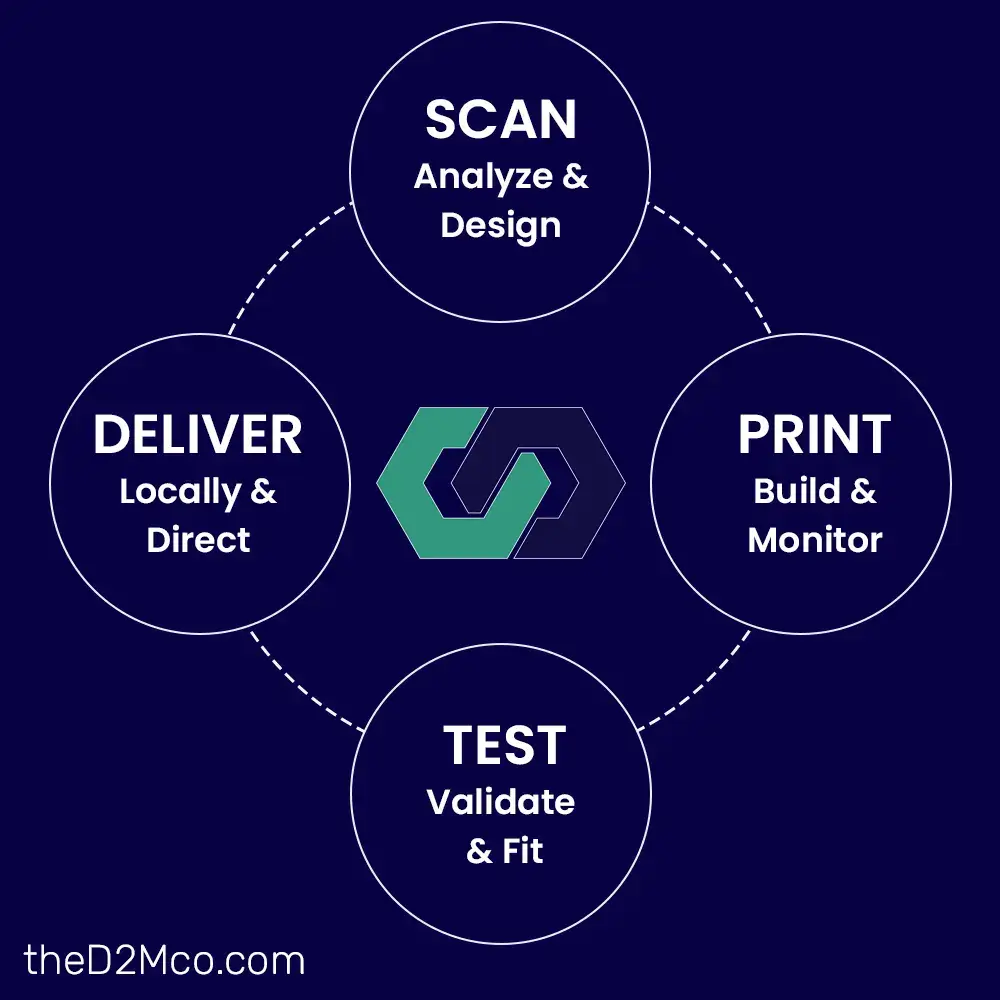

The path to a resilient, future-ready supply chain is not a linear one; it’s a dynamic cycle of strategic action. This new blueprint, enabled by Additive Manufacturing, transforms a traditional, brittle process into a flexible, on-demand workflow. The cycle begins with a critical first step:

- SCAN: Analyze & Design. The journey starts by assessing your existing parts and tooling. Leveraging modern 3D scanning technology, you can create high-fidelity digital replicas of physical objects that may lack blueprints. This process of reverse engineering allows you to analyze and optimize designs for additive production, ensuring they are lighter, stronger, and more efficient than their traditional counterparts. This also marks the genesis of your digital inventory.

- PRINT: Build & Monitor. With a production-ready digital file, parts are built layer by layer using industrial AM systems. The process is monitored with advanced in-situ sensors to ensure quality and consistency from the very start. This on-demand production capability eliminates the need for expensive tooling and long lead times associated with conventional manufacturing.

- TEST: Validate & Fit. A part is only as good as its performance. Before deployment, every component undergoes a rigorous validation process. This includes non-destructive testing (NDT), such as 3D scanning, to check for internal defects and ensure dimensional accuracy. Mechanical testing, like tensile and compression analysis, proves the part meets its required strength and durability standards, adhering to global certifications.

- DELIVER: Locally & Direct. The final, certified part can then be produced locally, minimizing reliance on long-distance shipping and its associated costs and risks. This distributed manufacturing model provides a powerful geographic hedge against geopolitical instability and logistical disruptions, ensuring you can deliver parts exactly when and where they are needed.

Implement Digital Inventory Management Systems

Transitioning to digital inventory systems provides real-time visibility into stock levels and demand patterns. This enhances forecasting accuracy, reduces waste, and supports just-in-time manufacturing. Integrating digital inventory with AM capabilities further streamlines operations and accelerates time-to-market. The digital file becomes the primary asset, replacing physical goods with a secure, easily accessible, and version-controlled virtual library.

Strengthen Supplier Relationships and Diversify Sources

Building strong relationships with suppliers and diversifying sourcing strategies mitigate risks associated with geopolitical tensions and raw material shortages. Collaborative partnerships and flexible contracts ensure continuity and adaptability in the face of disruptions. Additive manufacturing complements this by allowing you to work with a network of certified AM partners, who can produce your parts on demand, regardless of their location.

Leverage Advanced Technologies for Enhanced Decision-Making

Incorporating technologies such as AI, IoT, and blockchain into supply chain operations enhances decision-making and operational efficiency. These tools provide predictive analytics, real-time tracking, and secure data sharing, enabling proactive responses to potential issues. AI can be used in the design phase to create optimized parts, while IoT sensors can monitor production for quality control, and blockchain can secure the traceability of a part from raw material to final delivery.

By adopting these strategies, manufacturers can build resilient, efficient, and future-ready supply chains. To begin your journey and secure your competitive advantage, a structured approach is essential.

Next Steps:

- Assess Your Current Supply Chain: Identify vulnerabilities and areas for improvement.

- Explore Additive Manufacturing Solutions: Consider how AM can address specific production needs.

- Invest in Digital Tools: Implement inventory management systems and advanced analytics platforms.

- Foster Supplier Collaboration: Develop strategic partnerships and diversify your supplier base.

The four-step cycle of Scan, Print, Test, and Deliver is the proven roadmap to supply chain resilience. But navigating this transformation requires a deep understanding of the technology, materials, and processes involved. To accelerate your journey and gain access to the tools and expertise you need to implement this new blueprint for success, we invite you to register for an account, and to get in touch with any questions.