In Saudi Arabia and Qatar, leading industries like oil and gas, aerospace, automotive, and defense manufacturing demand precision, efficiency, and innovation. Central to meeting these demands is 3D metrology, the advanced measurement science used for capturing accurate, detailed three-dimensional data from physical objects. From quality assurance to reverse engineering, 3D metrology enables industries to enhance accuracy, reduce errors, and accelerate production processes.

Understanding 3D Metrology

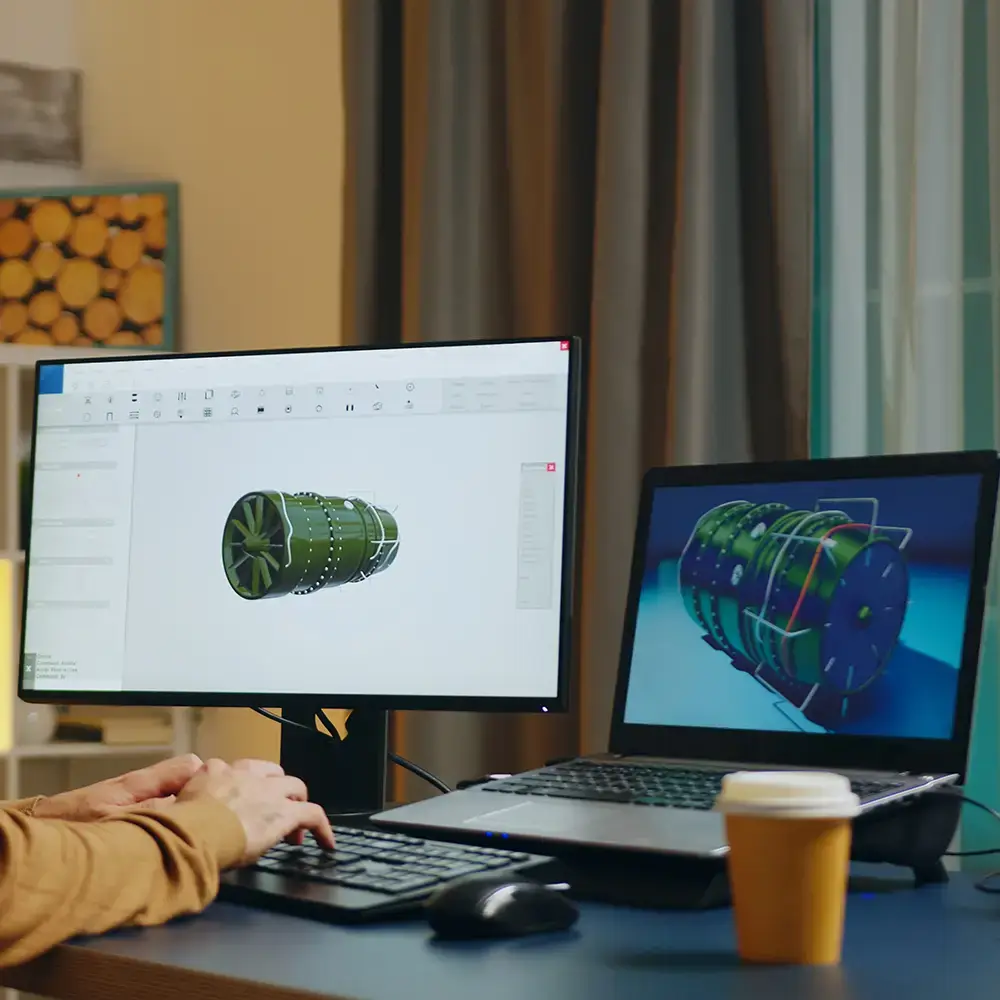

3D metrology encompasses technologies such as laser scanning, photogrammetry, and structured-light scanning. These methods digitally capture the complete geometry of components, creating detailed digital models that precisely reflect physical objects. Compared to traditional measurement tools, 3D metrology is faster, more comprehensive, and significantly more accurate, especially for complex geometries and large-scale parts.

Traditional vs. Modern Techniques

Previously, dimensional inspections relied on tools like Coordinate Measuring Machines (CMM), gauges, and manual measurements. These traditional methods, while accurate, were slow, labor-intensive, and limited in scope. Modern 3D metrology, particularly laser-based scanners, addresses these limitations by rapidly acquiring extensive datasets that reveal even subtle deviations across surfaces.

Industry-specific Applications in Saudi Arabia and Qatar

Oil & Gas and Energy

In the Gulf region’s robust energy sector, 3D metrology helps verify complex structures and equipment. It enables efficient as-built modeling of plants and platforms, facilitating precise retrofitting, maintenance, and reverse engineering of legacy components. Additionally, its non-contact nature makes it ideal for inspecting sensitive or hazardous equipment, significantly reducing downtime and operational risks.

Aerospace and Aviation

Aerospace manufacturers and MRO facilities require meticulous precision. 3D metrology accelerates inspections of turbine blades, airframes, and intricate engine components, ensuring high accuracy in significantly less time than conventional methods. It also supports local aerospace manufacturers in reverse-engineering critical aircraft components, boosting regional self-sufficiency.

Manufacturing and Transportation

In automotive, rail, and heavy manufacturing industries, rapid quality inspections enabled by 3D metrology drastically improve production line efficiency. It facilitates quick identification of manufacturing defects, reduces the need for rework, and ensures product consistency, helping regional manufacturers maintain international competitiveness.

Spotlight on KSCAN-X: An Industry Leader

The KSCAN-X stands out as a premier industrial-grade scanner, highly suitable for Gulf region applications. It integrates multiple advanced scanning technologies, offering unmatched versatility, accuracy, and usability:

- Multi-Mode Laser Scanning: Supports large-scale scanning with 84 laser lines, capturing large surfaces quickly and accurately (0.075 mm accuracy). It easily transitions to a finer mode (27 crossed laser lines) for detailed scans at up to 0.03 mm accuracy.

- Integrated Photogrammetry: Delivers consistent measurement accuracy over extensive objects, ideal for large-scale infrastructure in oil, gas, and aerospace.

- Deep Hole Scanning: Specialized mode precisely captures recessed geometries, crucial for inspecting complex industrial components.

- Wireless and Portable: Dual battery power and wireless connectivity ensure maximum flexibility and mobility on industrial sites, including challenging environments.

- Fast Calibration and User-Friendly Controls: Quick calibration (under 20 seconds) and intuitive, one-touch operation optimize productivity and reduce user fatigue.

Best 3D Scanners 2025

As industries increasingly adopt digital measurement technologies, here are leading scanners shaping the 3D metrology landscape:

KSCAN-X: Versatile multi-mode scanning, outstanding accuracy, and portability, perfectly suited for large structures and precision tasks.

3DeVOK MT: Compact,3DeVOK MT handheld scanner delivering high precision (up to 0.02 mm accuracy), ideal for small-to-medium parts and reliable on-site inspections.

TrackScan-P: Combines laser scanning and optical tracking for real-time, highly accurate inspections of large assemblies and production lines.

These 3D scanners are setting benchmarks for quality and efficiency in industrial measurement tasks across key sectors.

Real-world Success with 3D Metrology

Several industrial scenarios in Saudi Arabia and Qatar demonstrate 3D metrology’s transformative impact:

- Hydropower Component Inspection: Rapid and accurate inspection of turbine blades and generators, ensuring strict compliance with engineering tolerances.

- Automotive Reverse Engineering: Efficient replication of automotive components using detailed digital scans, significantly accelerating the reproduction of spare parts.

- Aerospace Component Certification: Dramatically reduced inspection times for critical aerospace parts, enhancing productivity and ensuring compliance with stringent regulatory standards.

These examples illustrate how 3D metrology elevates quality control, expedites manufacturing processes, and supports strategic industrial localization goals.

Driving Industrial Excellence

In Saudi Arabia and Qatar, adopting 3D metrology is not merely beneficial – it is essential. It allows industries to uphold exceptional standards, streamline production workflows, and proactively identify potential manufacturing issues. Tools like the KSCAN-X empower regional industries to perform rapid, comprehensive inspections and precise reverse engineering, positioning businesses to achieve operational excellence and robust competitiveness in the global market.

By embracing 3D metrology, regional industries in the Gulf are equipped to meet tomorrow’s industrial demands today, driving sustainable growth and innovation.