We help you reimagine the way you create products. Design innovative parts with optimal characteristics and performance properties. Reduce product weight, materials, and costs. Convert physical items into digital 3D files, re-engineer them, store their data in a digital inventory and unlock the potential of on-demand additive manufacturing. Create a digitized workflow, where software is used to design parts, control, and manage their production.

Part (inventory) audits

- Assessing physical inventory (or inventory data) for AM suitability.

- Heat map of where the most suitable parts may be formed from non 3D data.

Business case development

- Using the information gathered from the part audit, we help our customers understand where the business case is and where the most suitable AM investment strategy lies.

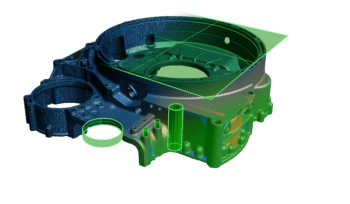

Reverse engineering & DfAM

- We assist customers convert physical components into usable 3D data for further processing. We may then proceed to alter the design to make it more suitable for additive manufacturing.

Digital libraries

- The final component is the creation of a digital library of components that have been lined to a particular AM technology, ready to print and perfrctly suited for their final application.