- August 29, 2023

- Posted by: TheD2MCo

- Category: News

The dental industry is conservative by nature – dentists, lab owners, and technicians all value the stability and consistency that come with being established in the space. But as exciting technological advances streamline manufacturing and lab processes and make it easier than ever to grow to scale, dental industry players are embracing the benefits of 3D printing.

3D printing dental models and surgical guides has been widespread but the adoption of printing dentures has been slow-going. As a longtime 3D printing product manager, I believe it’s important to outline exactly how our solution can provide tangible, practical results that matter to dental labs, dentists, and patients.

Closing labor gaps and rewarding skilled dental technicians.

According to a recent survey by LMT, more than one third of lab owners (34%) named recruiting and retaining qualified employees as one of their top challenges for 2023. In the US, many dental technology training programs for technicians have shut down over the last two decades. Research by Zippia indicates that the average age of a dental technician is 43, and almost 60% of dental technicians are over 40 years old – and the younger generation isn’t rushing to replace them.

This is particularly significant considering that the average age of Americans continues to skew older, and the need for dentures is only projected to increase in the coming years. The good news is that digital technology means that manufacturing dentures requires less oversight, taking much of the tedious work and manual labor out of the process for lab technicians. With 3D printing, labs can continue their lab production at the same rates, or even higher levels, without needing to constantly scramble to recruit and hire new technicians.

Streamlined processes and efficacy.

The digital denture production process ensures that results are repeatable, consistent, and reliable. When it comes to 3D printing, a complicated set of dentures and a simple set will take the same amount of time to produce. External factors, such as inaccuracy caused by human error and fatigue as the workday continues, are practically non-issues when using 3D printing.

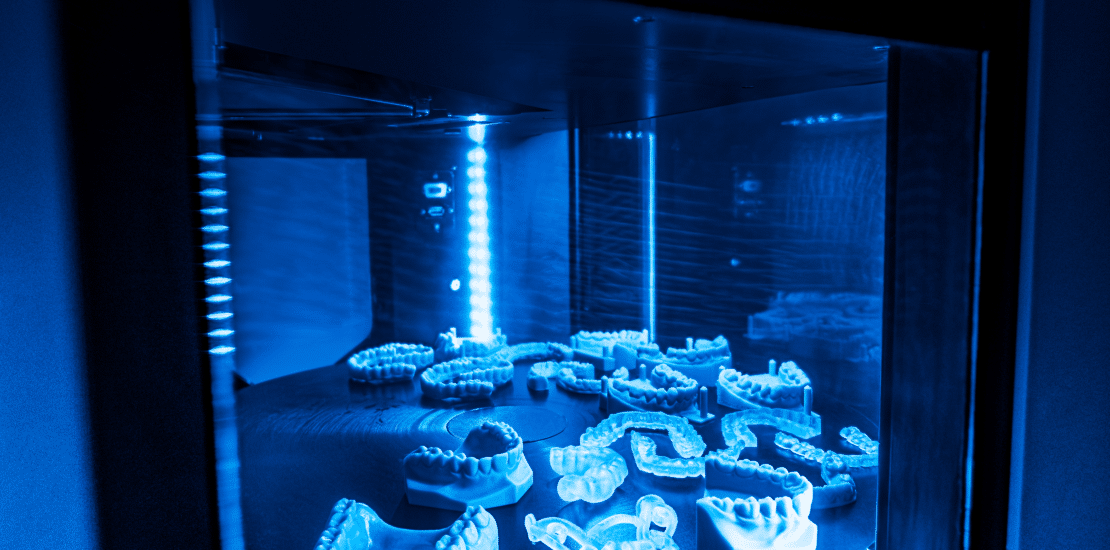

The best part is that due to the automated nature of much of the 3D printing process, labs can continue unattended production overnight, printing large batches of personalized denture cases. Lab techs don’t need to “babysit” the manufacturing while its ongoing and can instead focus on other tasks and let the technology handle the busywork without staff overtime.

Superior aesthetics and service for patients.

Our unique tech allows for the use of both transparent and opaque materials simultaneously, creating gradients and internal structures mimicking more closely a patient’s natural teeth and gums. With expanding shade choices, different hues and translucency levels, and even the ability to add imitation capillaries to the base and considering that 3D printing software is still evolving, the aesthetics of 3D-printed dentures will continue to improve in the years to come.

That’s not to mention that replacing a lost or broken pair of dentures is no longer an arduous, time-consuming, and expensive venture. Now, a patient can call their dentist, explain that they need to replace their dentures, and the lab can pull up their digitally stored file and produce a new product – all in less than 24 hours!

This opens up possibilities for patients, dentists, and labs to provide replacement services, including product warranties, which were impossible to implement in the past. Because turnaround time is much faster than with traditional dentures, both lab owners and patients alike can benefit from getting products created and in the mouths of customers, quickly.

Improved accuracy and a better final product.

Often with traditional dentures, patients need to head back to the dentist multiple times after receiving their product, because their dentures aren’t an exact fit to their anatomy. These visits are a time-consuming source of frustration for patients, and unprofitable for both dentists and labs.

Digital processes are less susceptible to human error or inconsistencies during manufacturing, and initial research has found that 3D printed dentures are, on average, more accurate than traditional dentures. Up until now, 3D printing solutions still suffered from inconsistencies rooted in the fact that the base and the teeth were produced separately, and the technician bonded them together. Stratasys’ PolyJet 3D printing technology is the only one offering monolithic printing of dentures, which results in less labor, higher accuracy on both intaglio and occlusal surfaces. Because everything is printed in one piece, our final product is significantly more accurate. Our unique, proprietary technology completely eliminates the risk of tooth debonding from the base, which occurs in approximately 3-5% of dentures.

When we get a set of dentures right the first time, there’s no need for endless rounds of follow-up visits as patients continually discover sore spots where their prosthetics aren’t fitting correctly. Instead, patients get a product that’s the correct fit for them immediately and come back perhaps once or twice for minor adjustments (and even that isn’t always necessary.)

Cost-savings with a major impact.

With inflation and the supply chain crisis creating strains on businesses throughout the dental industry, 3D printing can bring some much-needed release. The overall cost of a digital denture is much lower than the cost to manufacture a traditional denture, thanks to the automation, reduced manpower hours, and more efficient use of resources that come with the 3D printing process.

The material cost of a full 3D printed denture is typically between $20 and $40 per denture, which is significantly lower than the alternative. With traditional dentures, the set of carded teeth alone typically costs more than $40.

Thanks to the easing of processes and cost-savings offered by 3D printing, dental labs are now exploring branching out into producing dentures. These savings during production can be passed along to consumers, with manufacturers gaining the ability to offer more competitive pricing for dentures. More consumers will be able to afford dentures, which is a win for everyone.

3D printing for dentures offers a world of possibilities for labs, dentists, and patients. The digital process allows labs to expand production at lower costs and grow to scale, and patients to enjoy affordable products without repeated trips to the dentist. With streamlined production and improved accuracy, 3D printing is poised to revolutionize the way we create dentures. By embracing this technology, the dental industry can reap the benefits of a new era of efficiency and excellence in denture manufacturing.

Article written by Ron Ellenbogen.